- Joined

- Nov 13, 2022

- Messages

- 241

- Likes

- 109

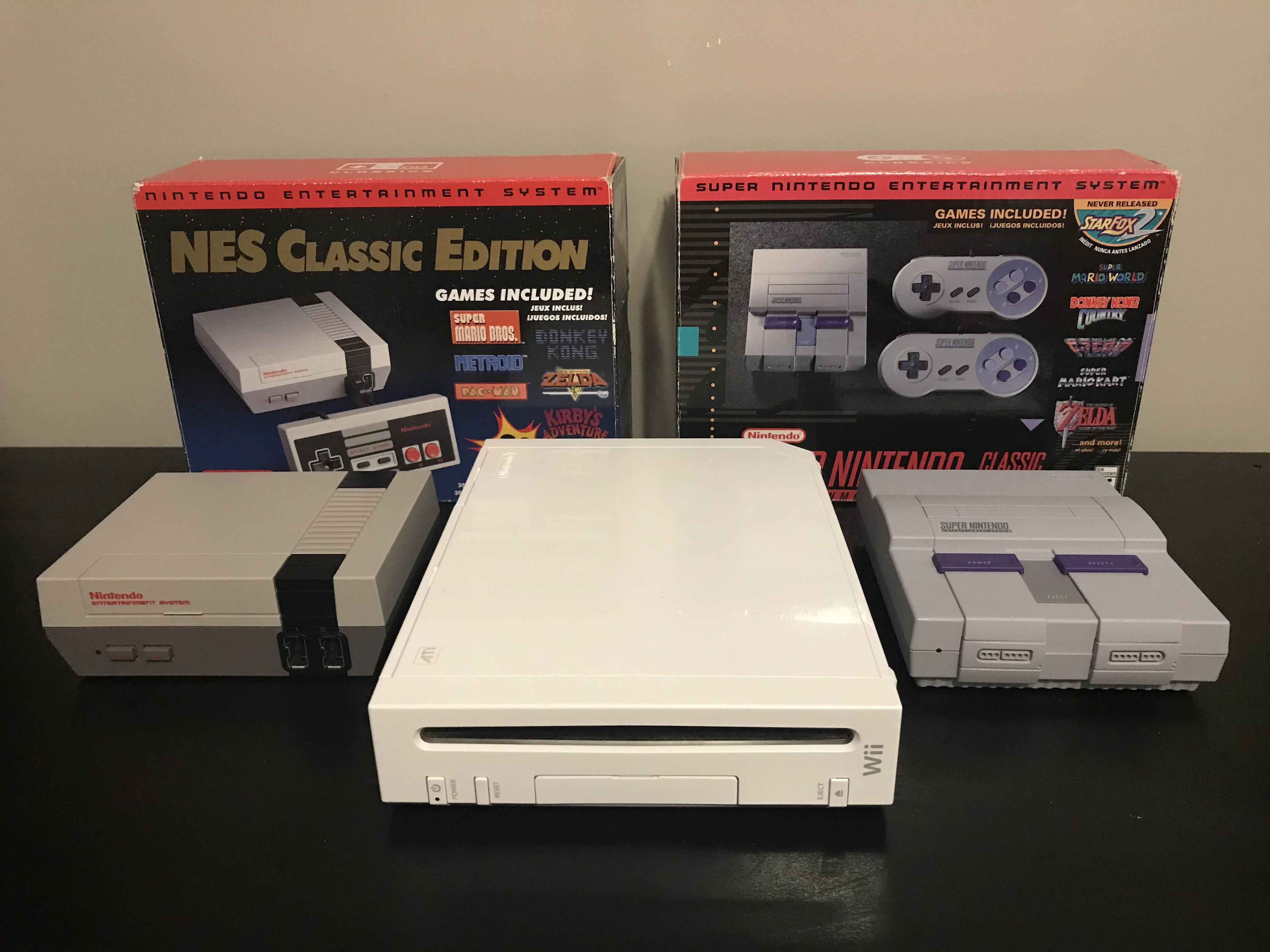

Hey everyone! This is the worklog for my next project, the Nintendo Wii Classic Edition. The idea behind this project is basically a modified version of Nold's Wii Micro, but stuffed inside a perfect replica (scale TBD) 3D printed Wii case.

It will include several extra features as well that can be found in the other Nintendo Classic Edition consoles such as HDMI video out and internal storage (I'll explain how I plan to achieve those later). It will use the same board and trim as the original Wii Micro, and incorporate similar features such as GameCube Controller support, Bluetooth, and the MX Chip. A couple extra features I'd like to add include an integrated sensor bar (probably just a 3rd party sensor bar wired up to the orignal port and placed on the front of the system), and an extra port on the front of the console (inside where the SD card slot would be on a normal Wii) that can be used to access the internal USB drive. Since we're back in the school year, I don't know how often I'll be able to post, but I’ll keep you all updated as much as I can! Wish me luck!

It will include several extra features as well that can be found in the other Nintendo Classic Edition consoles such as HDMI video out and internal storage (I'll explain how I plan to achieve those later). It will use the same board and trim as the original Wii Micro, and incorporate similar features such as GameCube Controller support, Bluetooth, and the MX Chip. A couple extra features I'd like to add include an integrated sensor bar (probably just a 3rd party sensor bar wired up to the orignal port and placed on the front of the system), and an extra port on the front of the console (inside where the SD card slot would be on a normal Wii) that can be used to access the internal USB drive. Since we're back in the school year, I don't know how often I'll be able to post, but I’ll keep you all updated as much as I can! Wish me luck!

Last edited: