TheFizz

.

- Joined

- Jun 9, 2024

- Messages

- 13

- Likes

- 7

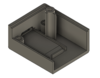

I modified a v1.2 case to accomodate a PD trigger board to use instead of a regular DC jack. @Wesk might want to add this somewere in one of his posts

This is for a HW-398 trigger board.

Make sure your trigger/decoy board is set to 9V

There are no guarantees that powering your console this way will not fry it. PS2 79XXX is rated for 8.5V input so do this at your own risk.

The print for me was a snug fit and I think you can just push the board in without a retainer but you risk displacing it. You need to push the buisiness end into the hole first and then push the rest of the board flat onto the platform.

You will need to use 2 M3x6 screws to mount a retainer. The screw holes are small enough for the screws to self tap. Make sure to not overtighten them else the standoffs will break off.

I am including a test part so you do not need to print the whole half to test fit your board.

CAD files are included so you can modify the design if necessary. The TestPart.step is also included and can be used to modify the other variations of the top shell.

This is for a HW-398 trigger board.

Make sure your trigger/decoy board is set to 9V

There are no guarantees that powering your console this way will not fry it. PS2 79XXX is rated for 8.5V input so do this at your own risk.

The print for me was a snug fit and I think you can just push the board in without a retainer but you risk displacing it. You need to push the buisiness end into the hole first and then push the rest of the board flat onto the platform.

You will need to use 2 M3x6 screws to mount a retainer. The screw holes are small enough for the screws to self tap. Make sure to not overtighten them else the standoffs will break off.

I am including a test part so you do not need to print the whole half to test fit your board.

CAD files are included so you can modify the design if necessary. The TestPart.step is also included and can be used to modify the other variations of the top shell.

Attachments

-

333.5 KB Views: 110

-

484.5 KB Views: 128

-

132.7 KB Views: 94

I really like this design style having the button up front, just a simple button with a 3d printed button cover. Had to make the hole a little bigger but it works really well. Would be nice if the case could be modified to allow for a specific switch to be mounted there instead of having to use hot glue though in the future.

I really like this design style having the button up front, just a simple button with a 3d printed button cover. Had to make the hole a little bigger but it works really well. Would be nice if the case could be modified to allow for a specific switch to be mounted there instead of having to use hot glue though in the future.